SunECG

SunECG: Solution for Customers Using Expanded Color Gamut Printing

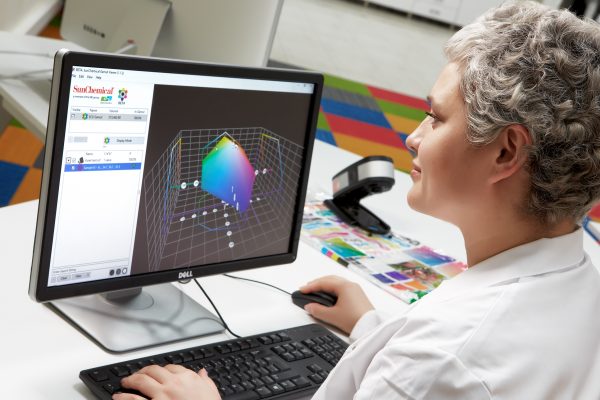

Sun Chemical has been working with Esko, the leading supplier of prepress software, to develop a seven-process-color industry standard for color management for printers and converters. The SunECG solution starts by taking you through an audit process first to ascertain the status of the presses and processes you have in place, and to ensure your process control is of sufficient quality to enable you to run expanded color gamut (ECG) printing successfully.

Assuming we’re able to validate the presses’ stability and repeatability, we will then supply an ECG ink set and run what we call a “press fingerprint” on the press. The press fingerprint exercise will print out many different combinations on overprints, which can then be measured with a spectrophotometer back into the Esko Equinox system, where an ECG profile is created. You can then specify the spot color required and Equinox will reference that profile and state the exact percentage required of each of the seven colors to achieve the desired solid color.

You can then specify the spot color required and Equinox will reference that profile and state the exact percentage required of each of the seven colors to achieve the desired solid color.

For printers and converters able to take advantage of ECG printing, the benefits are significant, as there is no need to change inks on the press because all of the work is being done in the prepress separation to ensure that the color required is built up across each print station.

Since the seven colors can be left in the press, changeover and make-ready time for each new job is greatly reduced, delivering substantial cost savings. Multiple designs can also be consolidated across one web/sheet, so there is no need for individual production runs for different jobs.

A further, optional benefit of an enhanced color gamut can also be gained in photographic image areas of the print, provided the artwork is still in the original RGB format and has not been compressed to comply with a standard ISO 12647 workflow.

Sun Chemical is developing tools for converters to access their process capabilities to understand the benefits of converting from spot color to ECG printing.

Customer Testimonials

“The latest Esko solution we introduced is Equinox, an extended gamut print solution that enables us to be more flexible in view of our customers’ needs. Esko Equinox turned out to be the best solution to meet the needs for extended gamut printing and to get prepared for the next technology step. By using Equinox, we are able to match about 95% of the Pantone colors.”

- -Markus Naegeli, Head of Marketing & Sales at K+D

“It is a major innovation being able to print Pantone™ colors with just seven inks. We can now offer higher quality, more saleable print with less color differentiation. We have now boosted our color space and regularly use extended gamut printing. We are also saving an average of 25% in inks.”

- -Evgeny Lungin, Head of Prepress for Uniflex

“Our 8-color press allows us to reap the full benefits of Equinox, with one printing unit still available for specific spot colors such as gold, silver and some shades of purple, that are difficult to reproduce. Today, whatever print jobs are requested, the same set of inks can be used, making gang printing easier and reducing press downtime.”

- -Cédric Ladroue, General Manager of Statim

“Standardization of the prepress process translates into faster make-readies and now we can print most jobs in up to seven colors. Besides cost reductions, we now get more jobs printed with the extended gamut and have also achieved a quality match of digital print with flexo. We now run about 60% of new jobs on Equinox.”

- -Tomasz Fiebich, Production Coordinator at Natalii

*Esko and Equinox are registered trademarks of Esko-Graphics BVBA.

Resources

Feel like learning more? Download our SunColorBox Guide.

Request